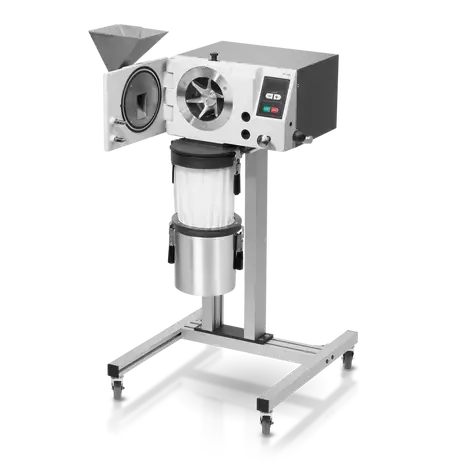

ROTOR BEATER MILL SR 300 with rotor, 240 mm filter hose and collecting vessel with distance rotor, 200-240V

ROTOR BEATER MILL SR 300 with rotor, 240 mm filter hose and collecting vessel with distance rotor, 200-240V

Final fineness: < 50 µm

- suitable for batchwise operation of larger quantities

- high final fineness

- adjustable speed for different applications

- easy cleaning thanks to exchangeable push-fit grinding insert, rotor and cassette

- grinding chamber, feed hopper and material inlet and outlet of stainless steel

- optional grinding inserts 180° for grinding of hard-brittle materials by additional impact

- optional distance rotor to reduce frictional heat

- removable hopper for easy cleaning

- electric engine brake

- defined final fineness due to bottom sieves with aperture sizes from 0.08 - 10 mm

- central locking device

- wide range of accessories including various collection and feeding systems, rotors and sieves

- Accessories

- NO

- Grind

- Rotor mills

- Quantitative unit

- ks

Dokumety ke stažení

ROTOR BEATER MILL SR 300 with rotor, 240 mm filter hose and collecting vessel with distance rotor, 200-240V