568416 - Quality control with AI 9V

By buying you get

809 Points

More than a purchase. You get service and expert advice. Ask which products and combinations are recommended for you.

Artificial intelligence in research, education and industry

The use of artificial intelligence in industry, education and research is becoming more and more important. The Quality Control with AI System model from fischertechnik is ideal for visualising this complex subject in a hands-on way since it creates a sustainable learning experience by linking theory and practice.

Visualizing quality assurance through AI with fischertechnik

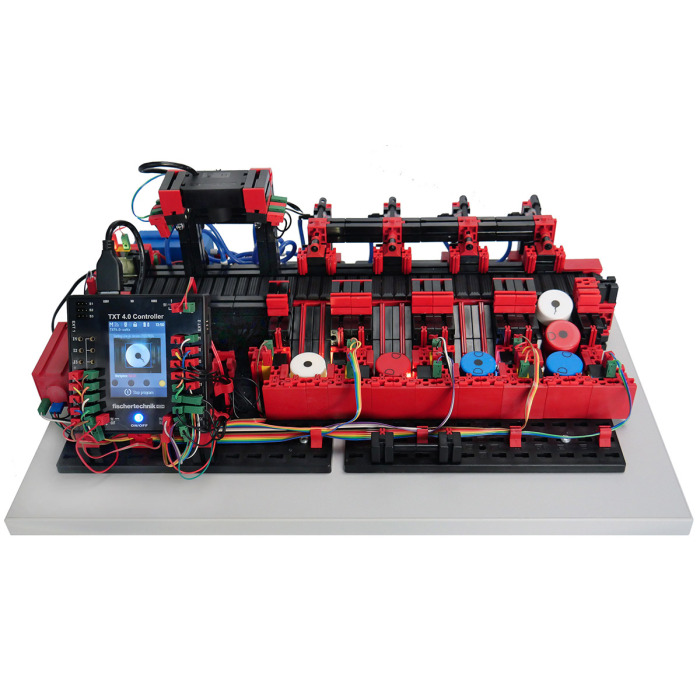

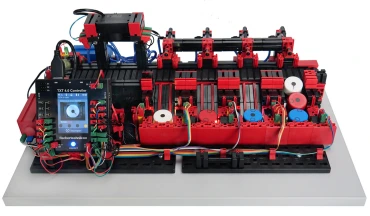

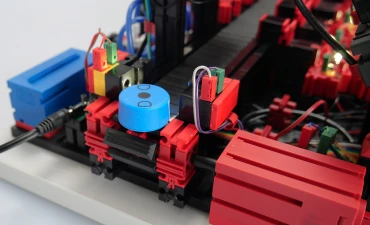

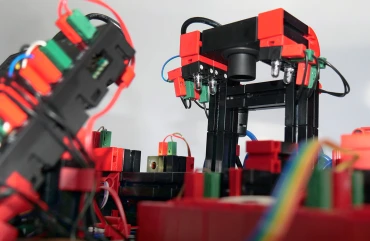

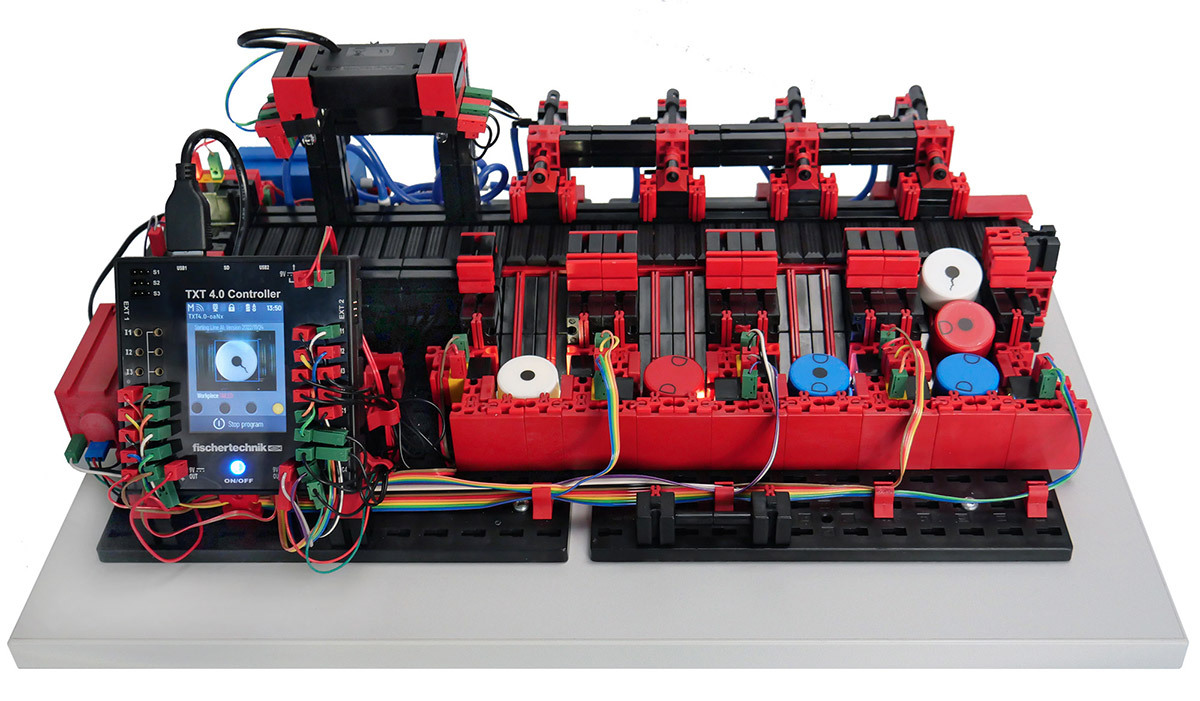

The use of artificial intelligence in quality control brings numerous advantages, which are already being used in the automotive industry for instance. Processes can be speeded up, fault rates and costs minimised and fault evaluation standardised. The fischertechnik sorting line is supplied with workpieces in three different colours. These workpieces are marked with three processing characteristics as well as different fault patterns. The workpieces are scanned by the camera and classified with the aid of the trained AI. Depending on colour, feature and fault pattern, the workpieces are then sorted by the artificial intelligence on the basis of their quality features. The AI used is realised with machine learning in Tensorflow, where an artificial neuronal network was trained with image data. The learned AI is executed on the fischertechnik TXT 4.0 Controller. The model's sequence control is implemented in the ROBO Pro Coding programming environment and in Python.

Generate your own AI applications

If you want to go a step further, you have the option of generating your own AI applications. The training is done in Python, for which a suitable example project is provided for explanation.

Model structure of the sorting line with AI

Sorting line for workpieces in 3 different colors (white, red, blue), with 3 different machining features (bore, gouges, bore+gouges) as well as different error patterns (bore out-of-round, bore missing, gouges missing completely or partially, cracks in the workpiece. These machining and defect features are simulated with corresponding adhesive labels on the workpieces. The workpieces are scanned by the camera and classified using the trained AI. Depending on the color, feature and defect pattern, the workpieces are then sorted into 4 different bays. The AI is implemented with Tensorflow and is run on the TXT 4.0 controller. Own AI models can also be generated. The training is done on a computer in Python. A corresponding example project is provided. The sequence control for the sorting system is implemented in the programming environment ROBO Pro Coding and in Python.

Technical Data

Size of packaging: 50,2 × 34,2 × 30,2 cm

System prerequisites of software: Windows 10, MAC OS, Linux, Android, iOS

Power supply system (Battery): power supply 9V/2,5A

System prerequisites of software: Windows 10, MAC OS, Linux, Android, iOS

Power supply system (Battery): power supply 9V/2,5A

- By age and focus

- Simulating

- Quantitative unit

- ks

568416 - Quality control with AI 9V